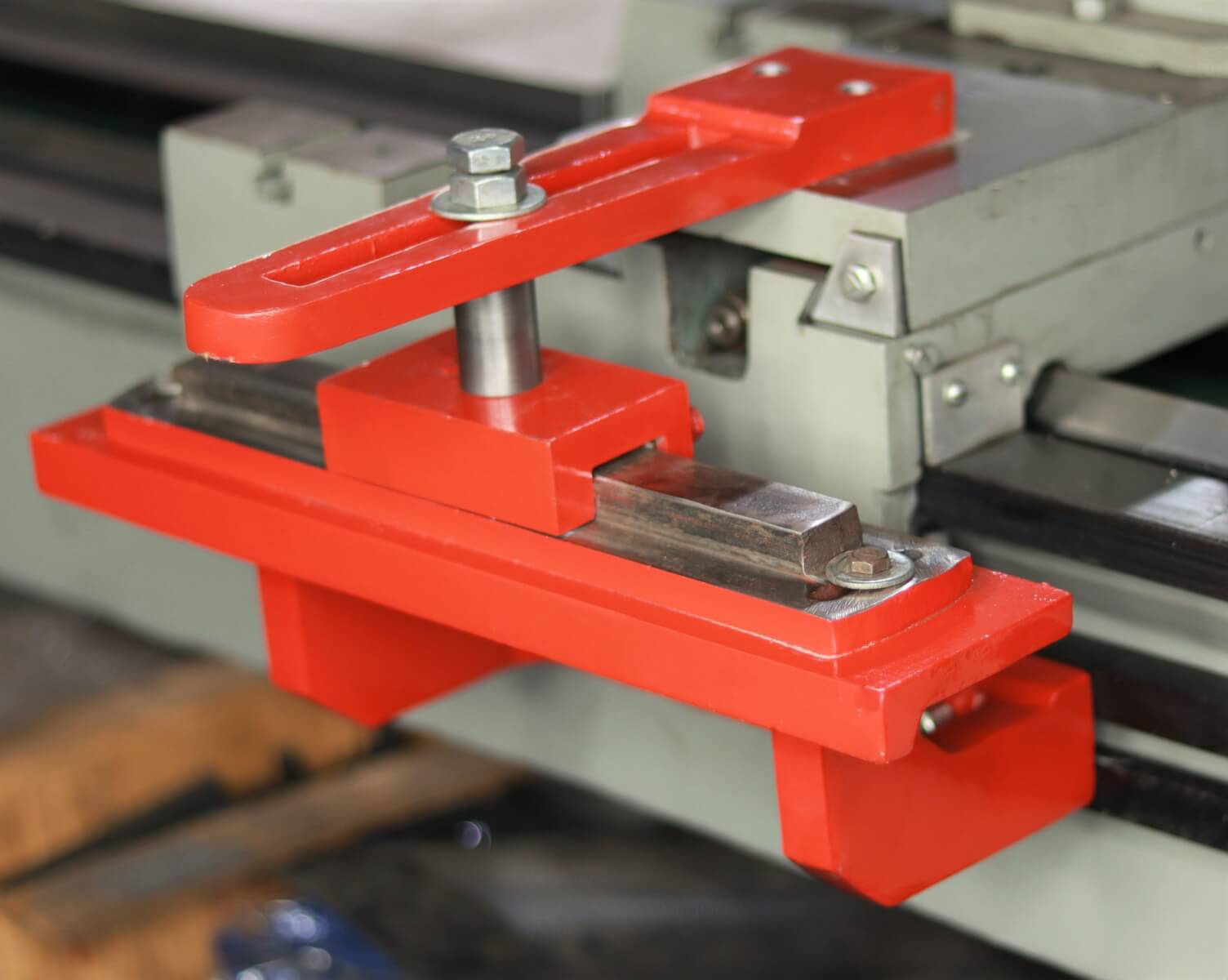

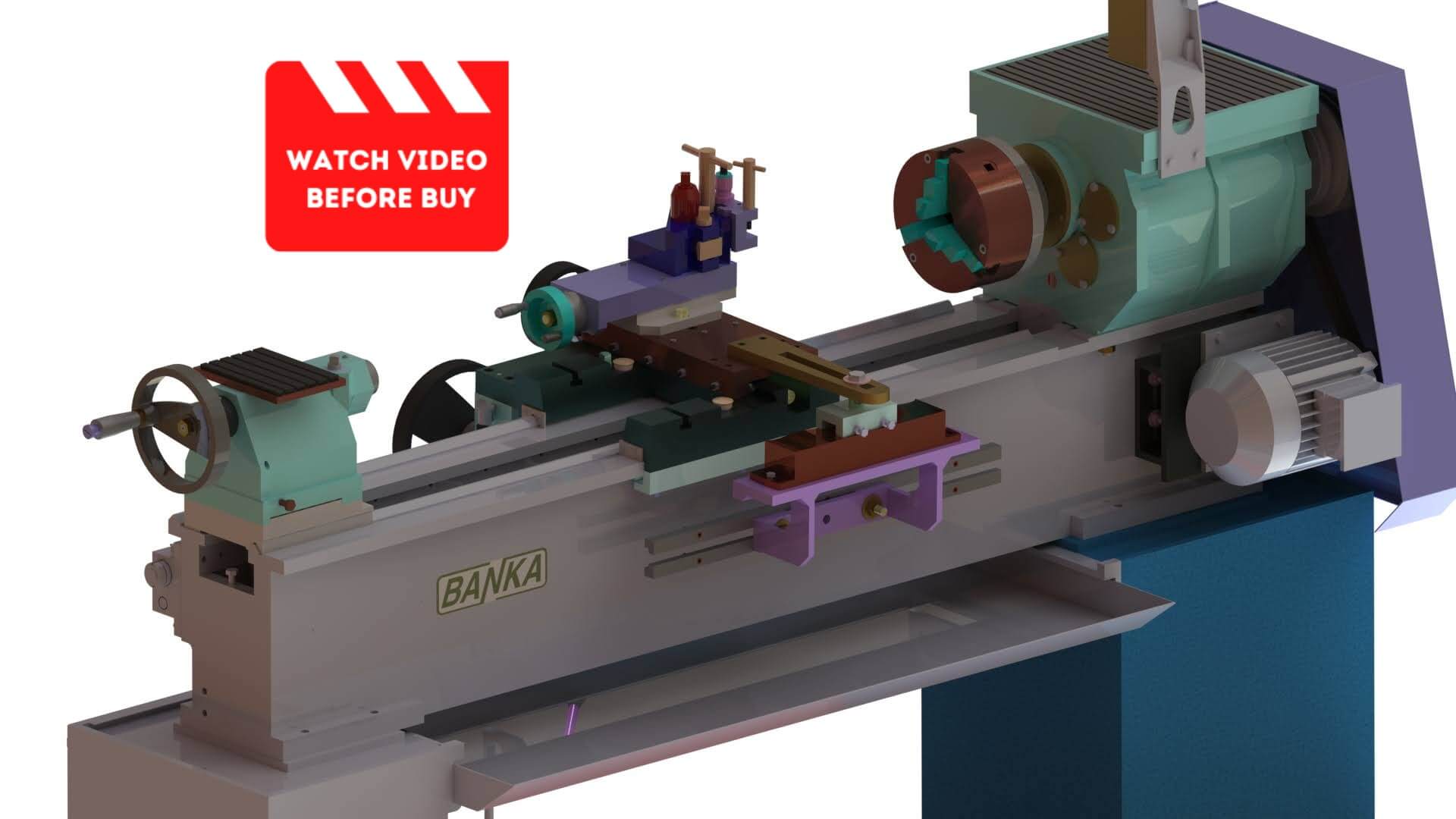

Taper Turning Attachment

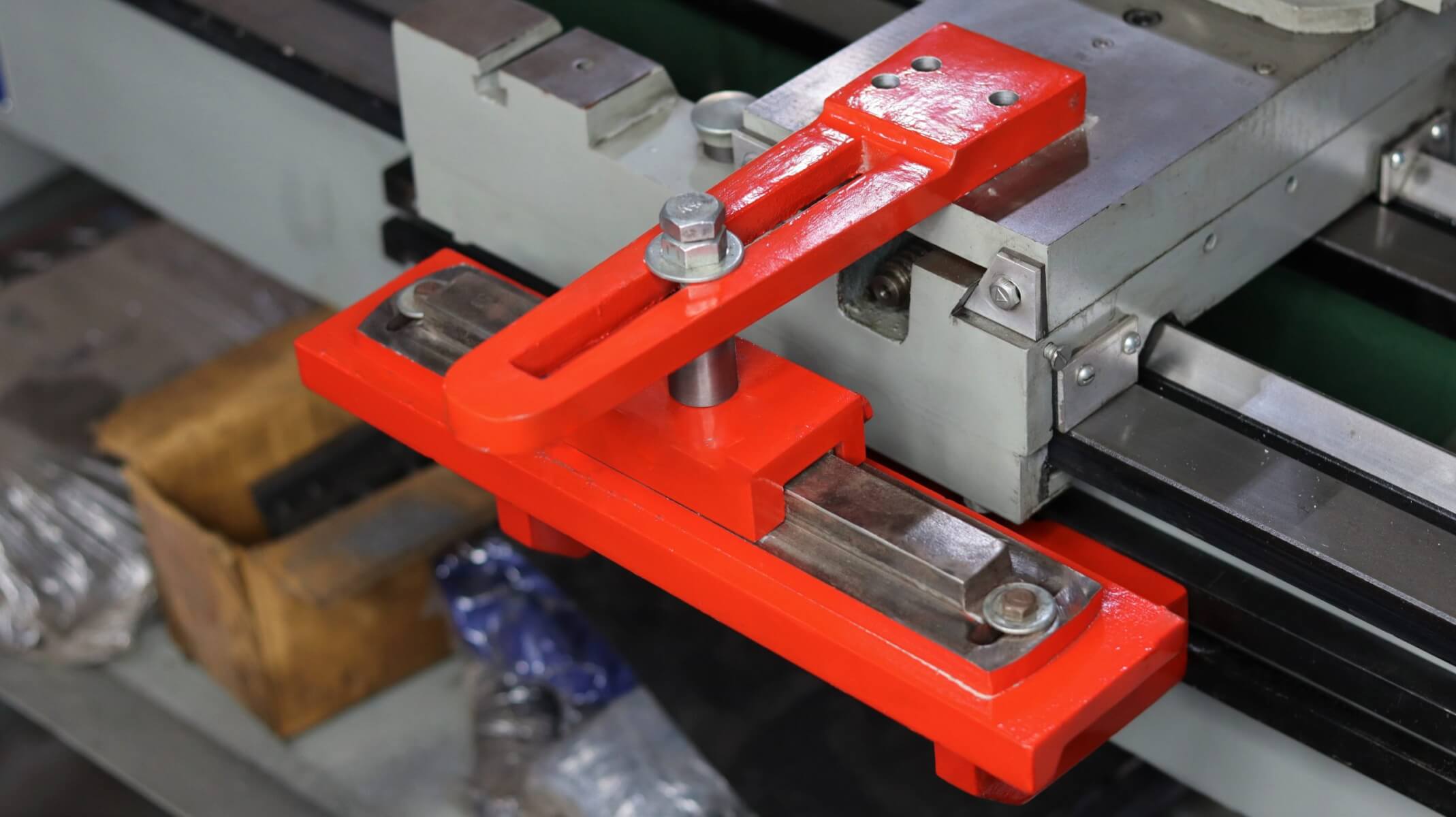

- Taper Turning Attachment is very much popular and fits all lathe machines.

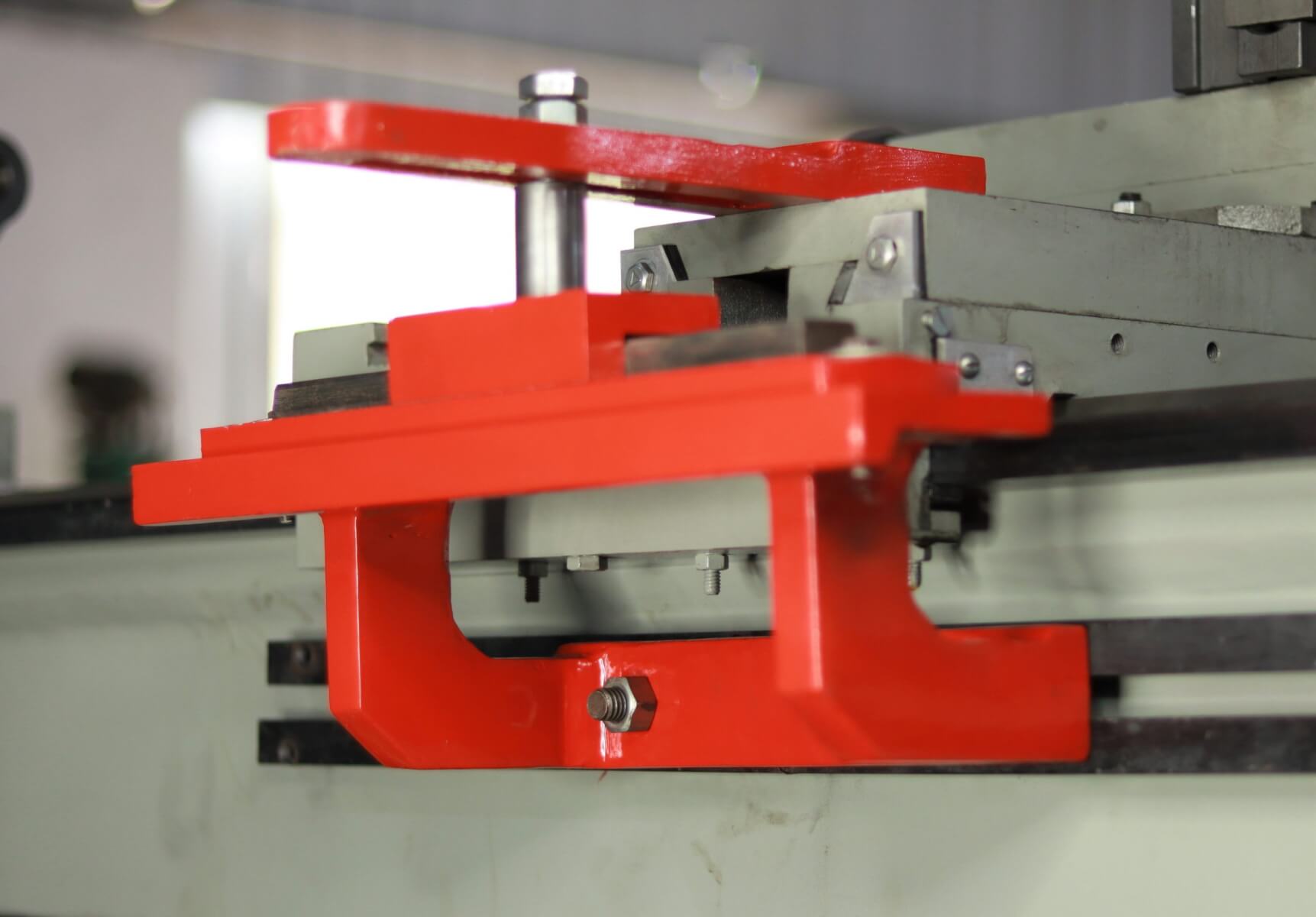

- In ordinary straight turning, the cutting tool moves along a line parallel to the axis of the work, causing the finished job to be the same diameter throughout.

- When the diameter of a lathe workpiece changes uniformly, from one end to the other, the piece is said to be tapered.

- Taper turning as a machining operation is the gradual reduction in diameter from one part of a cylindrical workpiece to another part.

- Tapers can be either external or internal. If a workpiece is tapered on the outside, it has an external taper; if it is tapered on the inside, it has an internal taper.

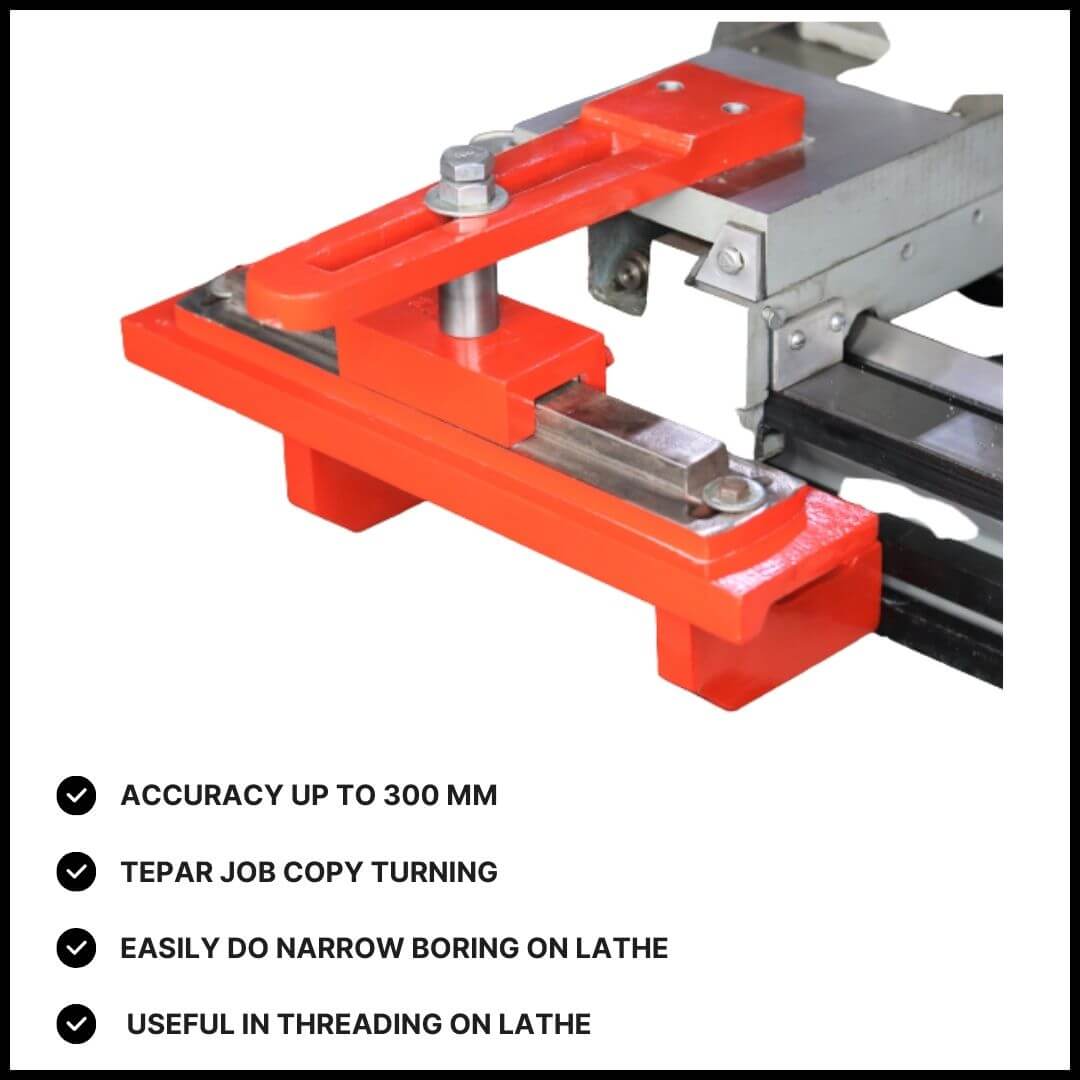

Taper Turning Attachment Advantages:

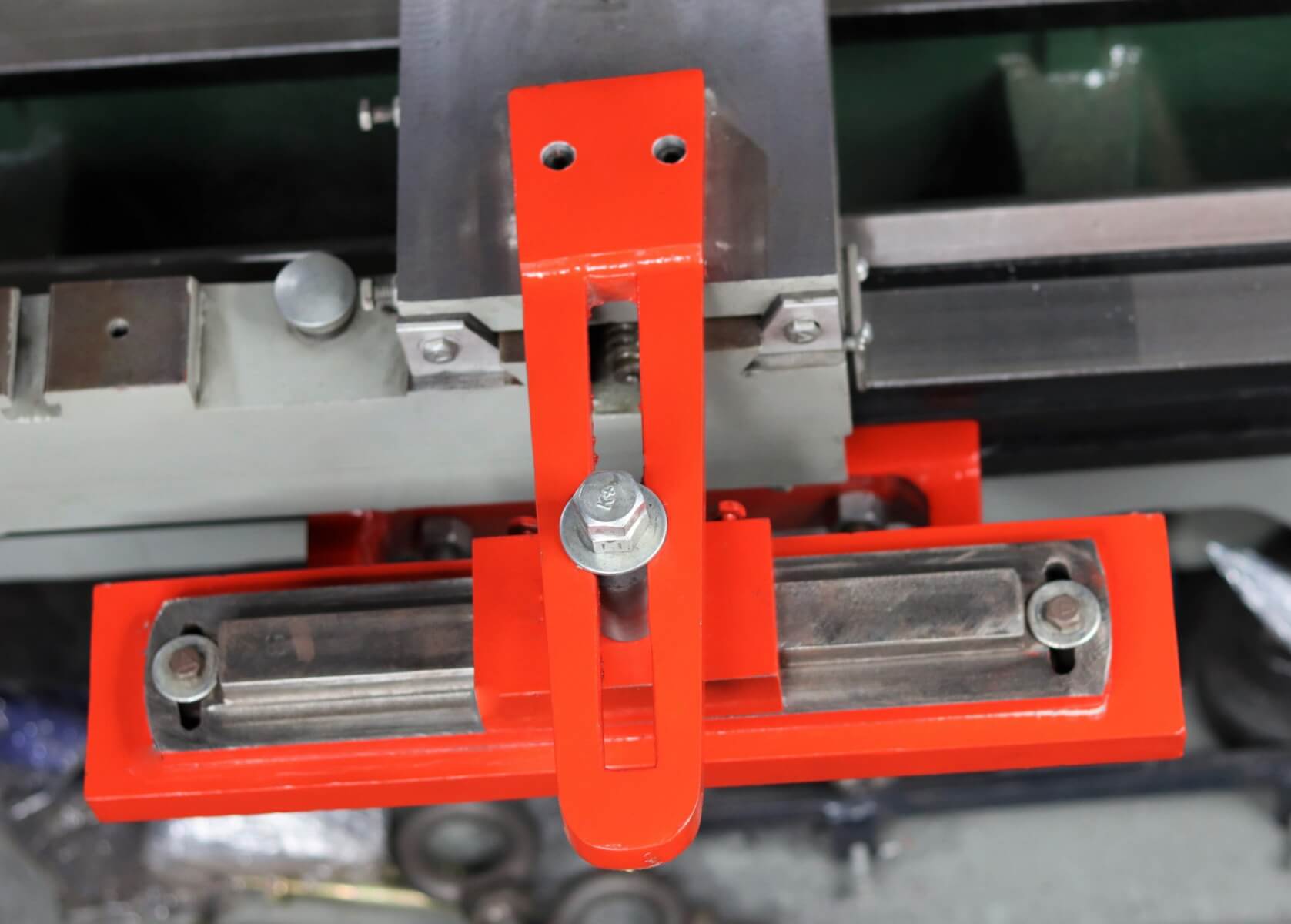

- Fast and consistent accuracy up to 300 mm Taper Turning job on the lathe.

- It’s useful in threading on the lathe workpiece inside as well as outside.

- Any length of the lathe workpiece can be tuned.

- At the set, the position accessory can be left.

- With taper turning, we can easily do narrow boring on the lathe machine

These are classified as follows :

- Morse Taper

- Used for drills, reamers, and lathe center shanks

- Brown & Sharpe Taper

- Used for taper shanks on tools (end mills, arbors, reamers, collets etc.) generally used on Brown and Sharpe machines

- Jarno Taper

- Used in lathe and drill spindles

- Standard taper pins (1/4 inch per foot)

- Used for positioning and holding parts together