| Fully heavy duty welded structure torsion free construction. |

| Cutting head up-down movement guided in Vertical pair of “HIWIN” Germeny linear Motion bearing |

| for jerk free movement. |

| Infinitely variable pressure controlled cutting feed & upward return rapid movement by hydraulic |

| cylinder. |

| Quick approach of cutting head upto the bar before cutting starts to enhance productivity by |

| pushing rapid Button. |

| Coolant tank with 100 Ltr. capacity and powered with electric coolant pump. |

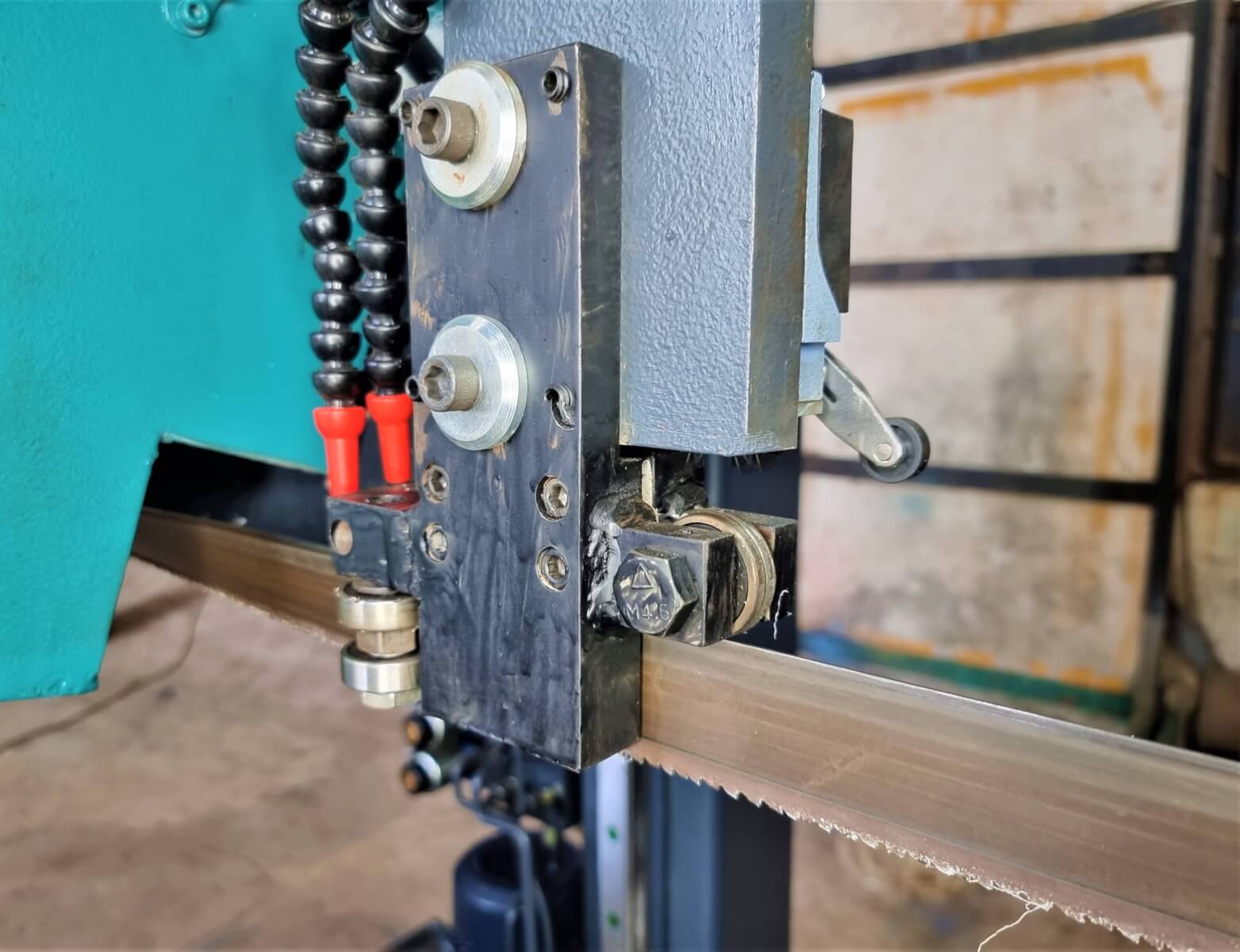

| Adjustable titanium carbide face blade guides with ball bearings at both side of cutting bar |

| Hydraulically operated main vice with double acting full stroke cylinder |

| Automatic return of cutting head much above the bar after cutting to safe height to save blade |

| damage by bar while indexing. |

| Hydraulically controlled automatic feed regulation through a state of the pilot operated hydraulic |

| valve to Optimize production and tool life. |

| High pressure coolant jets through blade guide helps coolant to enter in to the bar through blade |

| gullets to optimize productivity and tool life. |

| Manual blade guide setting with the opening and closing of moving vice |

| Cutting feed through infinitiely variable flow control valve with cutting pressure regulation, as per the |

| material property. |

| Heavy duty/Warm reduction gear box for blade rotation to minimize polygon effect to enhance tool |

| life, surface finish and minimize vibration during cutting. |

| Heavy duty energy efficient electric motor directly coupled to the gear box to minimize belt slippage |

| losses. |

| Control panel with necessary switch gear and step down transformer for control circuit |

| Split vice: – Machine is designed to offer burr free cutting with the help of split vice were in raw |

| material bar and Cut piece are clamped rigidly till the cutting head goes up after cutting which also |

| avoid rubbing of blade. |

| Stretching of blade through a Hydraulic operated or manual operated blade tension arrangement. |

| Linear motion guide rail & bearings on vertical columns are lubricated through oil pump. |

| Hydraulic power pack with sufficient oil tank capacity and necessary control elements is provided on |

| the machine. |

| Cutting feed and rapid reverse of cutting arm. |

Categories:Bandsaw Machines

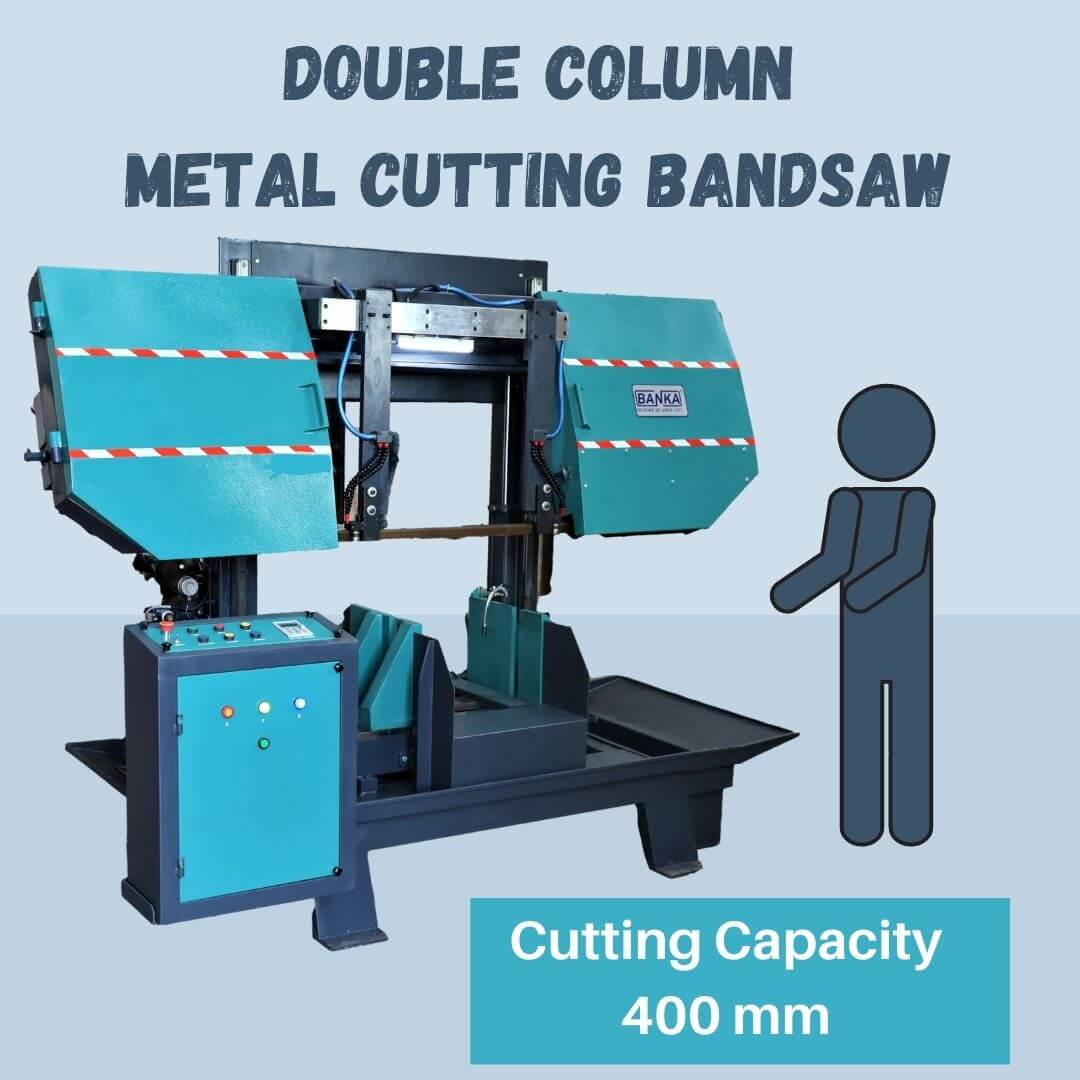

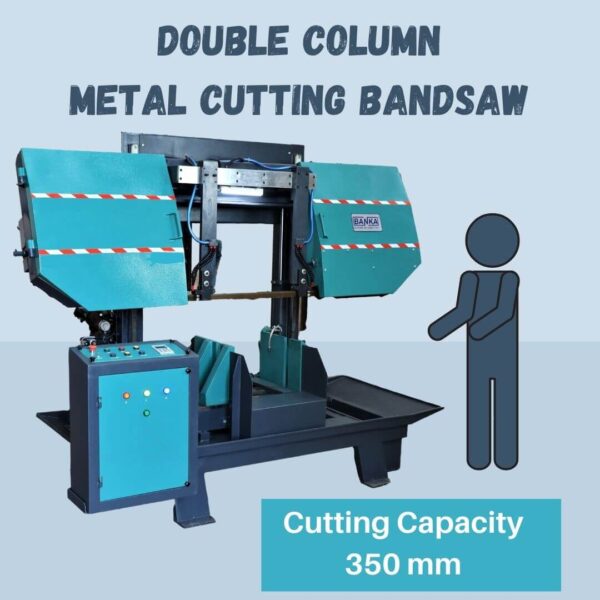

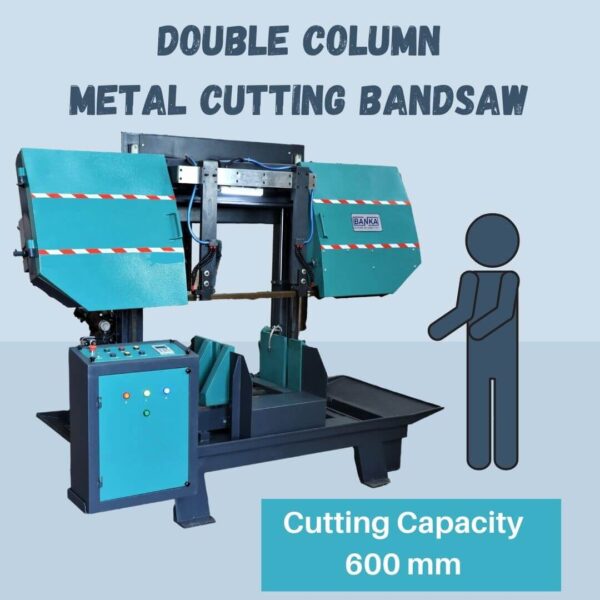

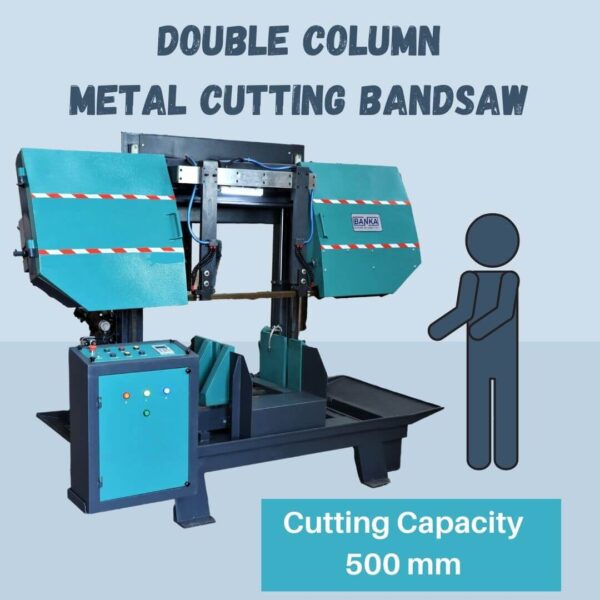

Bandsaw Machine Double Column Automatic Horizontal Model BANKA 400MM

0 Reviews

Availability

In Stock

₹610,000.00

| Cutting Capacity – Round 400 mm dia., Square 400 x 400 mm |

| Blade Speed: 10 To 60 Mtr/Min in std |

| Main Motor : 3HP |

| Hydraulic Motor : 1HP |

| Coolant Motor : 0.15 HP |

| Supply : 415 V,50 Hz,3 Phase A.C. Supply Control circuit with 220V |

| Blade : HSS Bimetal 5200 |

| Floor Space:- 4000mm x 1000mm |

| Coolant tank – 100 Ltr |

| A.C. frequency control drive for infinite variation of band speed thru control panel. |

| Feed control valve. |

| Hydraulic or manual blade tensioning attachment. |

| Hydraulic main vice. |

| Hand Lubrication Pump. |

| Slide movement of cutting arm on linear motion guide with bearing. |

| Electrical control Panel with push button, emergency stops button, main isolator, Auxiliary contractor, and cable |

Related products

Fast & Free Shipping Over $200

Two-day delivery on selected products

Expert Customer Service

8:00 - 20:00, 7 days/week

Free Gift Wrapping

With your custom message