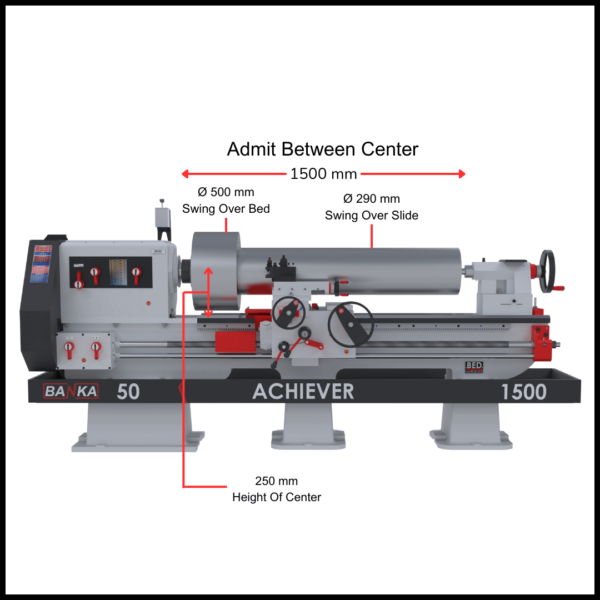

Essential Features :

|

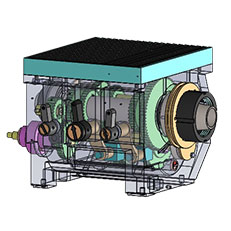

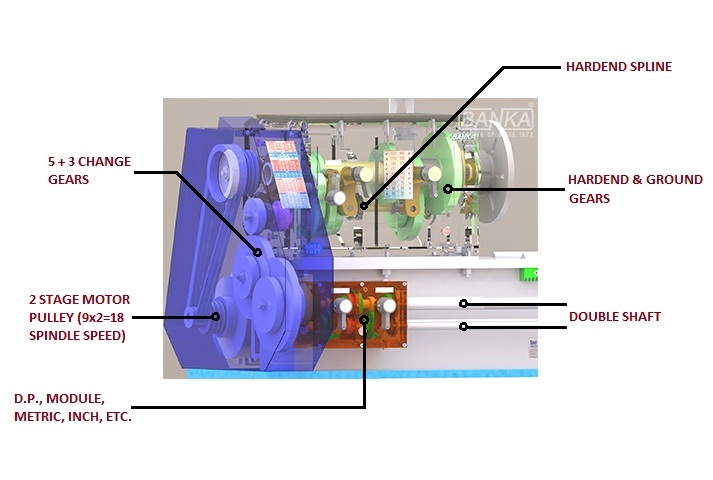

Headstock : The box-type constructed headstock with its rationally designed ridding arrangement gives a maximum rigidity performance free from thermal displacement and vibration.Its rigid-built hardened and ground spindle is supported in the study headstock by super precision roller bearing and ball bearing, capable of heavy duty and high sped applications. All gears, splines, spindles are made from 20 MnCr5 material and hardened ground. |

|

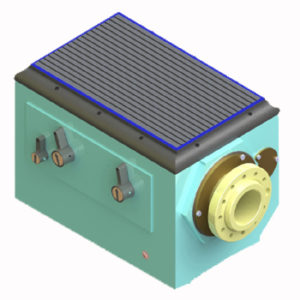

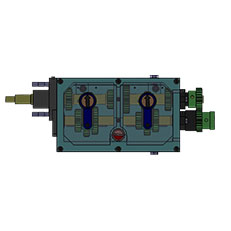

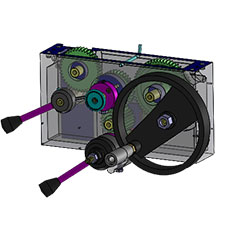

Gear Box : A specially designed gear mechanism is employed for this feed gear box. The easy to handle quick gear system provides an unusually wide range of feed and threads applications. Its outstanding features are that each selection of feed and commonly used threads (in metric, inch, module and DP) is instantly achieved through the combined operation of two levers with changing gears. |

|

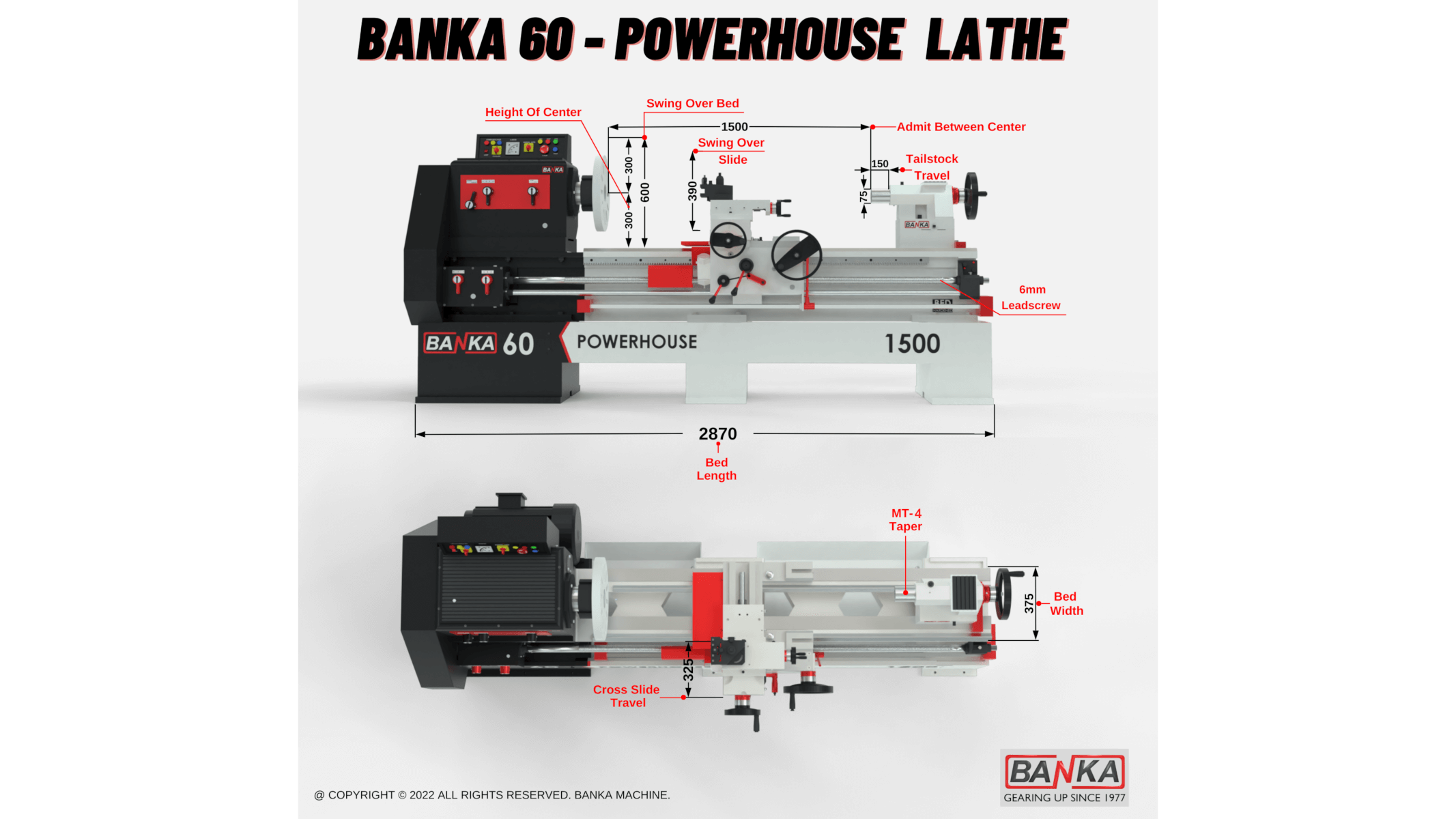

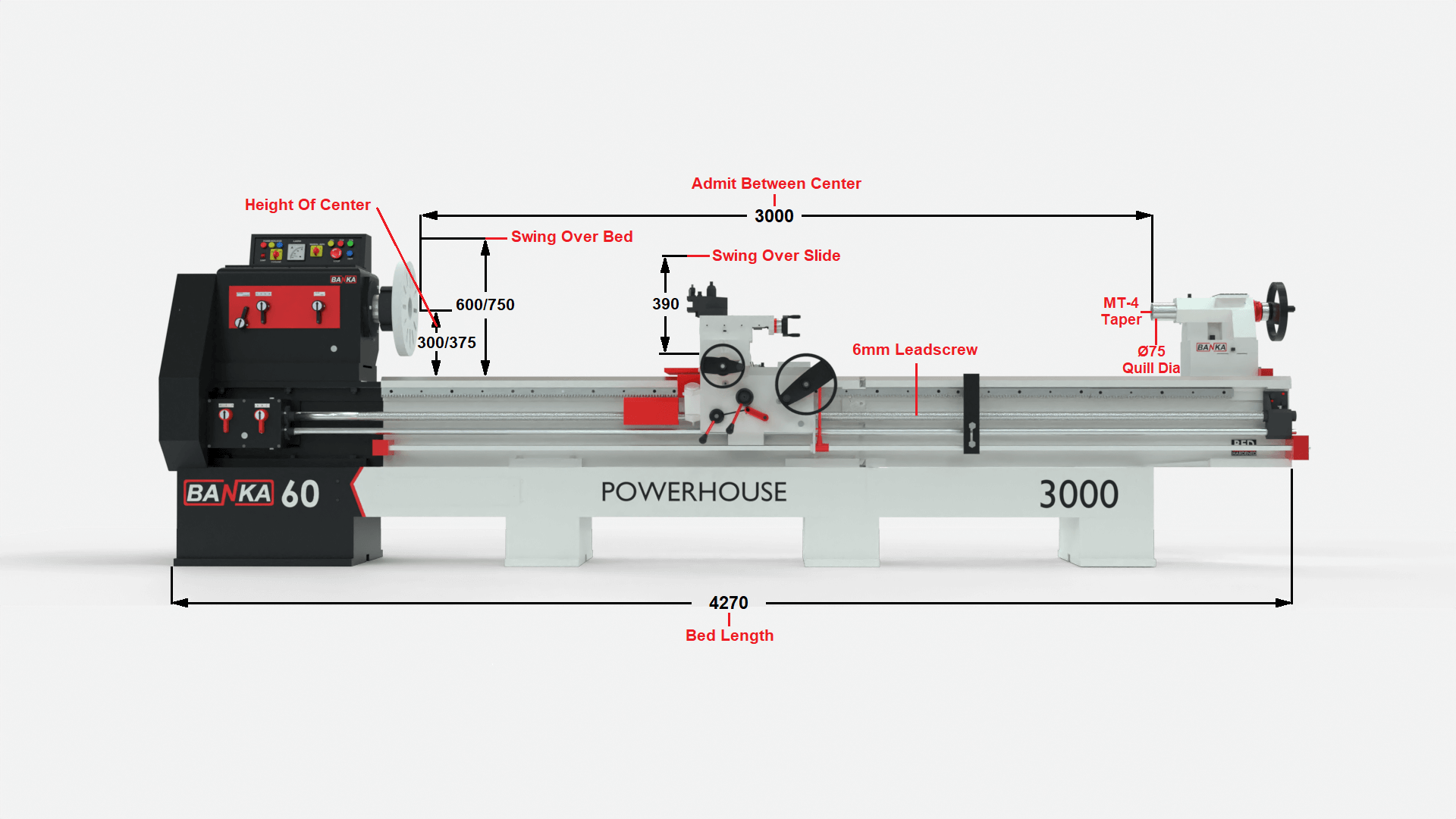

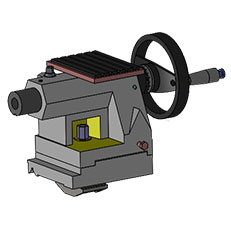

Tailstock : The sturdy construction of tailstock with Tang Shank type tailstock sleeve is capable of stable accommodation of heavy work.Double locking system ensures powerful tailstock clamping. |

|

Apron: Apron designed to totally enclosed oil bath system and lever type arrangement for automatic feeds. BANKA is providing self-handle which is used to run the machine in auto. This feature is very much usefully while operator will run the machine in auto, if an accident will occur then self-handle will automatically release and apron will stop immediately. It will reduce the further damage of gears and other risks. |

|

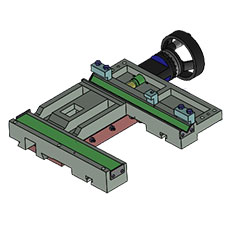

Carriage – Saddle: Turcite B Loner Bearing System coating between Carriage and Bed to provide extra cutting strength and long life accuracy. Also, it’s working as an anti-Friction system and gives smooth movement of Carriage on Bed. Without Turcite B bed accuracy will reduce up to 150 to 200 micron after 5 to 6 years. |

|

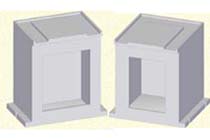

Leg : Legs having an appropriate wall thickness and robust design gives high rigidity and anti-vibration strength. |

|

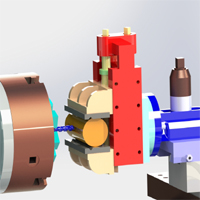

Quick Change Tool Post: In production engineering, the big advantage of a quick change tool post is that you don’t have to change the tools in tool post, just have to change the holders which already had set on the tool holder. It is time saving and increases the production. It’s safe and simple process while operation and has guaranteed lasting repetitive accuracy. Quick change tool post working parts are hardened and precision grounded. |

|

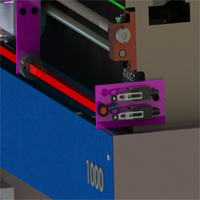

Carriage Stopper: Carriage Stopper is useful to stop carriage each time at a proper place as you have set. It also is known as the linear stopper. You can set six stoppers in carriage stopper as per your requirement. It is generally used in shaft turning works. |

|

Keyway Jaw: Keyway Jaw is used to make small keyways. Our Keyway vice is designed and developed as per the prevailing market trends and industry requirements. We are using high-grade raw material and precision engineering components to fabricate these machines. Owing to this, our range ensures high performance, reliability, efficiency, low maintenance requirements and durability. |

|

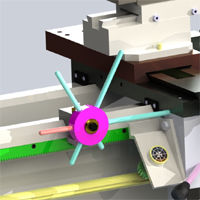

Third Shaft: The third Shaft is used in long lathe machines, suitable in above 7 feet length. It’s fitted with the bed of precision lathe machine below feed shaft. A handle has attached with the apron which is connected with Third Shaft, by which operator can stop the machine or can do reverse and forward operation at the time of turning the lengthy jobs. It saves the operator time, increases the production, easy to operate and maintenance accuracy. |

|

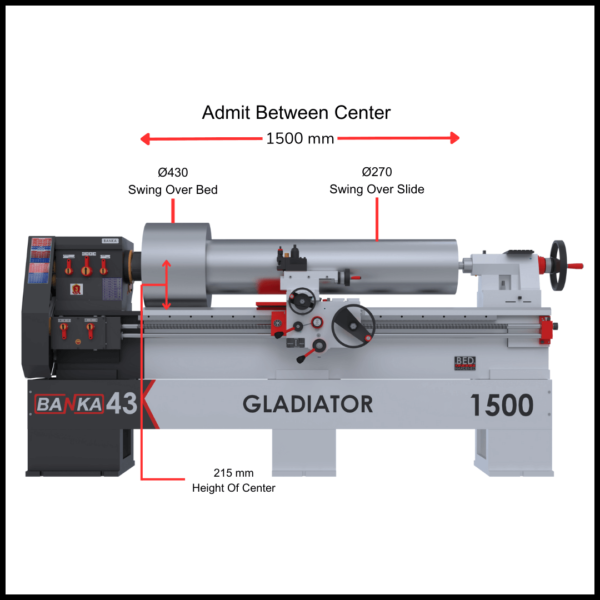

Hyperbolic Wall Bed: In heavy duty lathe, we provide Hyperbolic Wall Bed bed made from 25-grade casting and flame hardened up to 400 BHN. It is 2V & 2 Flate Special hyperbolic Bridge which gives extra rigidity and easy chip removal. |

Salient Features :-

- Headstock and gearbox gears hardened and ground.

- Bedways hardened and ground up to 400BHN.

- Turcite B anti- friction material on carriageways.

- Control panel & magnetic brake (optionally available on request)

- The metric dial on cross slide, Compound, and tailstock semi-universal gear box provides inch and metric thread without changing too many end trains gears.( universal gearbox optional available on request )

- Spindle speeds 48-1535 RPM in 16 H-L nos. spindle speeds.

- Alloy steel Spindle molesting on taper roller bearings.

- American LOO type spindle nose available on request.