Separate us from others

| Helical Gears:

We give constant strokes in the slotting machine and each stroke gives a reaction on the main gear teeth. For such continuous stroking, gears must be rigid to work for 15 years Taking into consideration the quality and accuracy of the job, we are using DP-8 Heavy Helical Gears in our slotting machine. It is made from GCI-25 Grade casting. With the help of helical gears, we can get more grinding works. Generally, spare gears give load on 1 tooth while helical gear gives load on 2 teeth so the possibility for break out very lies. Benefits of Helical Gears:

|

|

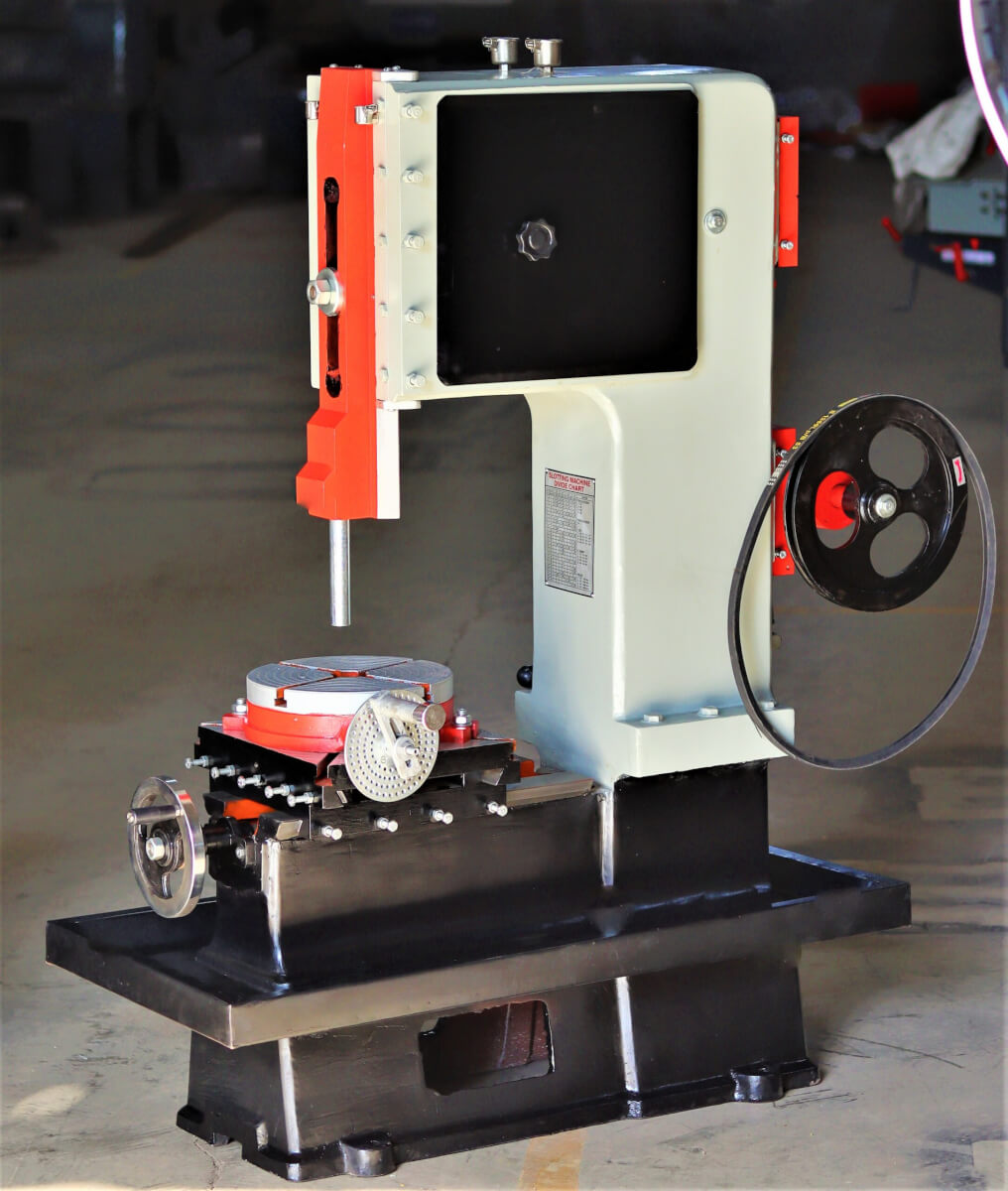

| Stroke Ram / Spindle:

Y-Axis – the main slide is the important part of the slotting machine. Accuracy and efficiency depend on Y-Axis. So our expert engineers put their best efforts while constructing this machine. Features of our Stroke Ram / Spindle:

|

|

|

Connecting Road / Base :

The benefit of Using Nylon Nut : Sometimes when oil gets over in the pump or the operator forgets to lubricating oil, there is no chance of any damage to the base because of that nylon nut. Even it also increases the life of Connecting road. |

|

Loading Hook :

We always think that machine should reach safely at customer’s floor. So considering transport problems and customers convenience, we are giving slinging hook inbuilt with the machine. The purpose to give such an option is to transit machines safely and without any damage. Our slinging hook carries weight up to 500-700 kg easily. |

Main Motor Pulley :

|