- It came with a motley assortment of the vintage cup and valve grinding/refacing stones, an additional quill with a long tapered spindle for internal grinding, and buffing (often missing from these kits), a full set of unused internal grindstones, and a spare drive belt.

- When new, this grinder must have cost a considerable sum.

- The motor spins at 2800 RPM and the spindle speed can be geared up or down using various diameter pulleys as required.

- Here’s a photo of it with the internal quill mounted, to center my external chuck jaws.

- Both the main shafts have been specially designed, and the worldwide precision bearing is used to fit the main shafts which are made of alloy steel heat-treated for high wear resistance, precision. as well as maintaining the lowest temperature for durability and stability.

- The motor base and the spindle bushing are adjustable.

- The motor is well designed with a special and nice appearance. The RMP of this motor varies depending on the size of the workpiece.

- This grinder is capable of grinding the workpiece to a minimum of 3mm in outer diameter and from 2mm up in inner diameter(bore) with accuracy within 0.003mm and a wheel finished surface(supplied with special attachments)

- The spindle bushing is made of cast iron and supported by three surfaces. Therefore, it is durable and elastic.

- Materials such as steel, iron, copper, aluminum, cast iron, plastics, porcelain, marble, regardless of being heat treated or not, can be ground on this machine which functions lie a cylindrical grinder. So it may lower the cost of production.

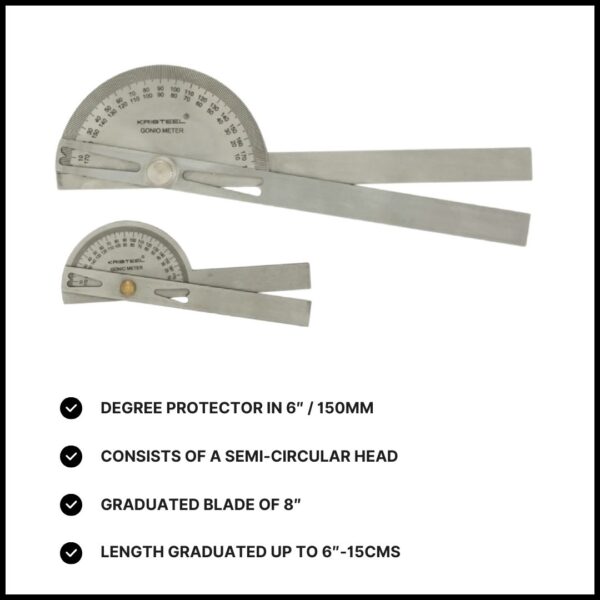

| Accessory | Suitable Model | Price (Rs.) |

| Grinding Fittings 6” | All Models | 23,500 |

| Grinding Fittings 8” | All Models | 25,500 |