-

×

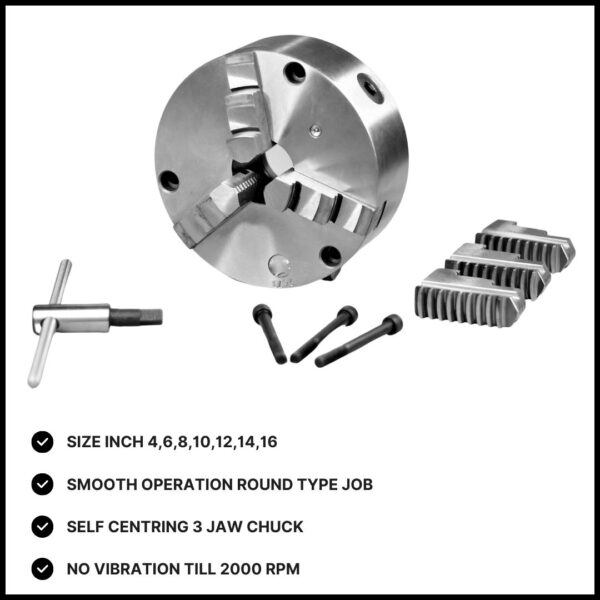

Lathe True Chuck

₹9,200.00

“Lathe True Chuck” has been added to your cart. View cart

Drill Chuck Arbor

0 Reviews

Availability

In Stock

₹2,450.00 Original price was: ₹2,450.00.₹2,090.00Current price is: ₹2,090.00.

A drill chuck arbor is a specialized component that allows you to attach a drill chuck to a machine tool’s spindle. It’s commonly used in milling machines, lathes, and drill presses. Here’s a comprehensive guide on drill chuck arbors, including their purpose, types, and usage:

Purpose of a Drill Chuck Arbor

- Adapter: It serves as an intermediary adapter that enables a drill chuck to fit into different types of spindles or tool holders.

- Versatility: Allows for the use of a drill chuck (which holds drill bits) in machines that require different shank types or sizes.

- Precision: Ensures accurate alignment and secure attachment of the drill chuck to the spindle.

Types of Drill Chuck Arbors

- Morse Taper Arbors:

- MT-1, MT-2, MT-3, MT-4, etc.: Commonly used in various machines, these arbors fit into the Morse taper spindles of milling machines, drill presses, or lathes.

- Usage: For machines with Morse taper spindles, ensuring a secure fit and easy changeover.

- Straight Shank Arbors:

- Plain or Straight Shank: Used in machines with collet or straight shank systems.

- Usage: For machines that use collet holders or have a straight spindle.

- R8 Arbors:

- R8 Taper: Common in milling machines, especially in the U.S.

- Usage: For machines with R8 spindle systems, commonly found in milling machines.

- BT and CAT Arbors:

- BT (Boring and Taper) and CAT (Catalog): Used in high-precision CNC machines and industrial settings.

- Usage: For CNC machines and precision milling operations.

- Jacobs Taper Arbors:

- Jacobs Taper: Typically used in older or specific types of drill presses and lathes.

- Usage: To fit drill chucks with Jacobs taper shanks.

How to Use a Drill Chuck Arbor

- Select the Arbor:

- Choose the arbor that matches the spindle type of your machine and the chuck type you plan to use.

- Install the Arbor:

- Insert the arbor into the machine spindle. Ensure it fits securely and aligns properly.

- Attach the Drill Chuck:

- Mount the drill chuck onto the arbor. Tighten the chuck to ensure it is securely attached to the arbor.

- Insert the Drill Bit:

- Place the drill bit into the chuck and tighten the chuck to hold the bit firmly.

- Adjust and Operate:

- Adjust the drill chuck and bit as needed, then proceed with your machining or drilling tasks.

Maintaining Drill Chuck Arbors

- Inspection:

- Regularly check for signs of wear, damage, or corrosion. Replace the arbor if necessary.

- Cleaning:

- Keep the arbor clean and free of debris. Use a brush or cloth to remove any chips or dirt.

- Lubrication:

- Apply light lubrication to the arbor and chuck to ensure smooth operation and prevent rust.

Description

Drill Chuck Arbours

- Milling & Drill Chuck Arbour

- Made from 16mnCr5, case hardened to 55-58 HRC.

- As per IS – 9097 (i) – 1979

- Precision ground run out 0.015 mm max.

- ISO : 30 JT-6 To ISO : 40 JT-3

- Colour – Silver

Drill Chuck Arbours Features

- Made from 16mnCr5, case hardened to 55-58 HRc.

- As per IS : 9097 (i) – 1979

- Precision ground run out 0.015 mm max.

- TOOLTECH service & guarantee apply.

| DRILL CHUCK ARBOUR SIZE | PRICE |

| ISO: 30 JT-6 | 2090 |

| ISO: 40 JT-2 | 1980 |

| ISO: 40 JT-6 | 1760 |

| ISO: 40 JT-3 | 2090 |

| M1TR/R-8 JT-6 | 1380 |

Related products

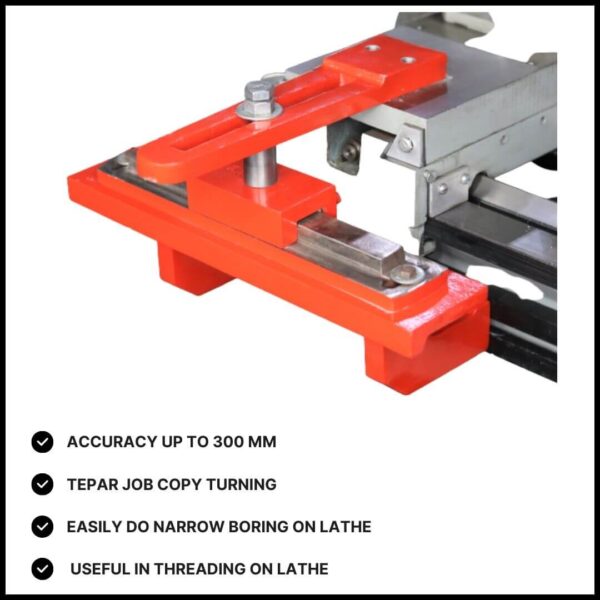

Taper Turning Attachment For Lathe Machine

Drill Chuck With Key

Key Way Attachment On Lathe

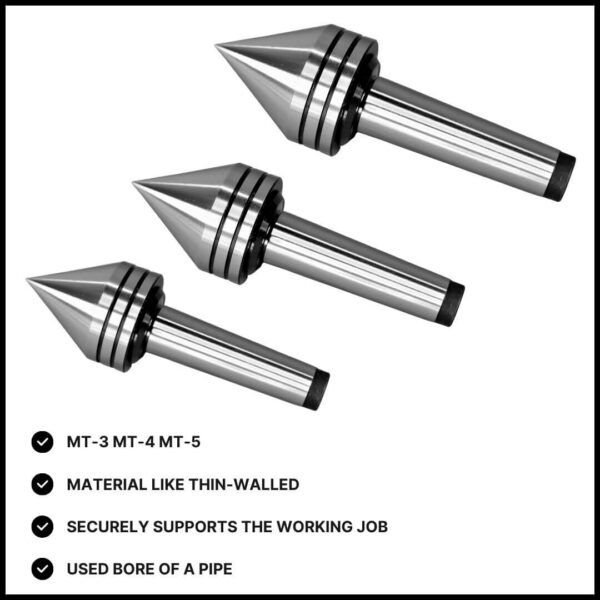

Lathe Revolving Center

Lathe Pipe Center

Fast & Free Shipping Over $200

Two-day delivery on selected products

Expert Customer Service

8:00 - 20:00, 7 days/week

Free Gift Wrapping

With your custom message